PERLITE SCREED

Light Floor Screed

Definition

It is a cement-based and perlite lightweight insulation screed that can be applied manually or by machine, providing heat and sound insulation.

TECHNICAL SPECIFICATIONS:

Color Gray

Dry Unit Heap Weight 500 ± 70 kg/m3

Compressive Strength C5 (TS EN 13813)

Flexural Strength F2 (TS EN 13813)

Reaction to Fire Class A1

Mixing Process 5 minutes mixing-2 minutes resting-2 minutes mixing

Pot Life 2 Hours

Working Time 20 minutes

Drying Time 4-6 days

Application Thickness 30 mm – 70 mm

Time Required for Opening the Floor to Pedestrian Traffic min. 2 days (this period may be longer depending on weather conditions).

* The above mentioned values are valid for + 23oC and 50% relative humidity.It is valid for C and 50% relative humidity. The time becomes shorter at high temperatures and longer at low temperatures.

USAGE AREAS:

It is used to create a flat floor before the final layer such as ceramic, parquet, laminate on floors exposed to light and medium-intensity pedestrian traffic in buildings. It contributes to sound and heat insulation on the floors where it is applied.

ADVANTAGES:

- High sound and heat insulation

- 5-7 times lighter than conventional screeds

- Its lightness helps buildings to be earthquake resistant.

- Practical and fast application opportunity

- Suitable for hand and machine applications

- Fireproof (A1 class)

APPLICATION CONDITIONS:

- Ambient temperature between +5 ° C and +35 ° C.

- Avoid application in very damp and / or hot weather.

- Avoid application under strong wind and direct sunlight.

- It should not be applied on surfaces that are frozen, melting or have the risk of frost within 24 hours.

USAGE INSTRUCTIONS:

The application surface must be clean, free from dust and oil, solid and dry. If there are residues on the surface (concrete, adhesive, paint, etc.), the remains should be scraped and cleaned.

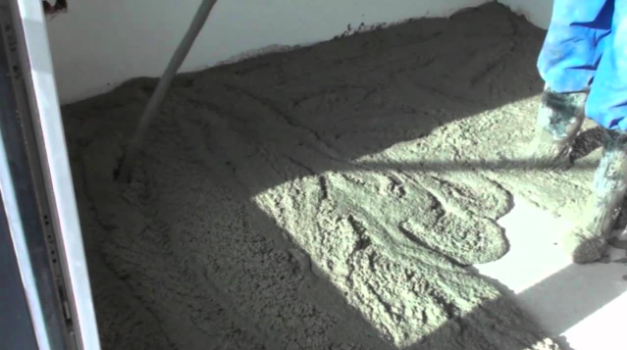

An average of 10-12 liters of water should be added to a 20 kg bag of PERLITE FLOOR SCREED, mixed in the application machine at low speed and the prepared mortar should be applied by spraying. In manual applications, the mixture should be made in accordance with the mixing times specified with a low speed mixer and should be leveled by applying to the surface with a steel trowel.

One day after the application, depending on the climate conditions, the surface is irrigated twice in the shade, morning and evening, for at least 3 days.

Warning:

No foreign material should be added into the mortar, each bag should be used as a whole and attention should be paid to the specified water ratios. All tools used after the application should be washed with water before they dry. The specified times are valid for 20 ° C surface and ambient temperature, the time is longer at low temperature and shorter at high temperature. The application conditions given in the Technical Data Sheet must be complied with. Otherwise, the final product performance of the product may be affected by application methods and ambient conditions.

PACKING:

It is prepared in a 20 kg craft bag, with shrink wrapped pallets.

CONSUMPTION:

5.5 - 6.5 kg / m2 for 1 cm screed thickness2

APPLICATION TOOLS:

Screed application machine, low speed mixer, gauge, steel trowel.

APPLICATION SURFACES:

Gross Concrete, Concrete, Cement Based Leveling Concrete

STORAGE AND SHELF LIFE:

It should be stored in its unopened original package in a cool and dry environment. It should not be left under direct sunlight. Shelf life is 1 year from the date of production under appropriate storage conditions. It should be stored in its unopened original package in a cool and dry environment. It should not be left under direct sunlight. Shelf life is 1 year from the date of production under appropriate storage conditions.

APPLICATION LIMIT:

It should not be applied directly on metal, wood or wooden surfaces. It is not applied on plaster surfaces. It is recommended to apply higher Strength Alum product in areas with high pedestrian and vehicle traffic. It is recommended to apply Insulated Terrace Screed on floors exposed to outdoor weather conditions and rain such as terraces and balconies.

SECURITY PRECAUTIONS:

Work and worker health clothing, protective gloves, goggles and masks should be used during the application. Due to the irritating effects of uncured material, in case of contact with skin and eyes, wash immediately with plenty of soap and water. If swallowed, seek medical advice immediately. Food and beverage materials should not be allowed in the application areas. It should be stored in places out of the reach of children.

S22: Do not breathe dust.

S26: In case of contact with eyes, rinse immediately with water and seek medical advice.

S29: Do not empty into drains.

S24 / 25: Avoid contact with eyes and skin.

S37 / 39: Wear suitable protective gloves, goggles / mask.

S46: If swallowed, seek medical advice immediately. Show the container or label.

Risk Phrases:

R7 / 8: Irritating to respiratory system and skin.

R41: Risk of serious damage to eyes.

R43: May cause sensitization by skin contact.

RESPONSIBILITY

Our company is not responsible for application errors that may occur if the product is used outside of its intended purpose or if the technical application conditions and recommendations mentioned above are not followed. The data in this technical sheet contains the information on the date they were written. The manufacturer reserves the right to change them.

Conforms to TS EN 1383 standard

CE Document

Public Works Pos No: 04.481